Background

The

Bridge Design Project primarily used West Point Bridge Design Software and

K’nex to show engineering students the basic concepts about how to build a

bridge and how the design affects its performance. West Point Bridge Design

helps students model, test, and optimize a steel highway bridge based on

realistic specification, constraints, and performance criteria. Below is the

link to a blog from a member of group 8 indicated their feeling of West Point

Bridge Design after using only a few time.

During the

process of learning how to interpret the data given by West Point Bridge

Design, some ideas of design had already been getting rid of because they could

not pass the truck test, see below.

Figure 1: A successful design in West Point Bridge Design

If a bridge

could not pass a simulated test how could that design and structure ever be

feasible enough to make a prototype. The designs which passed the test, needed

to improve because the high cost and inability of the K’nex pieces to be that

exact size or lay at that angle. Using the data gather from West Point Bridge

Design we could now start building plausible physical bridges out of K’nex.

K’nex behave more closely to a real

bridge than compared with West Point Bridge Design. It has to be built piece by

piece from nothing. There’s no sample bridge support be given like one West

Point Bridge Design. Thus, building a K’nex bridge a feasible idea and

blueprint is needed, a blueprint that could be found on a West Point Bridge

Design model that passed the truck test. West Point Bridge Design tests showed

that a bridge with top and bottom trusses is more stable than that only with

one side of truss, due to the more options the weight has to distribute. Thus

our initial, 24 inch K’nex bridge was born.

Figure 2: First design of K’nex bridge, 24” span

The

goal of this project is designing the most serviceable K’nex bridge by truss

analyzing. The ideal bridge would be loaded maximum loading with the lowest

cost after several forensic and static analyses.

Design Constraints

The

bridge span for the final design is a thirty-six inch minimum. The width of the

final design must be greater than three and a half inch. The bridge must be a

feasible prototype design to a real bridge, meaning that a scale car must be

able to fit through the bridge, the constraint for this was that a three inch

by two inch tube be able to fit continuously through the span of the bridge.

Design Process

The goal of our bridge is to design a most

severable bridge with the lowest cost. Our 24” inch bridge was mostly build using

the 1.125” inch chord. In the final bridge, the bridge size is increase, so we

use 3.375” long chord instead of the 1.25”one. By testing how different angles

work in the bridge. By the calculations we got the middle section is the part

which undergoes most of the tension, so we change the middle part to smaller

truss, so it can separate the tension of the loads. At the fist design we made

the end members very strong as they must negate the force and are under as much

force as the middle ones, so we get rid of some chord to short the cost. The

original design also had numerous non-fixed member connecting the two halves.

This was untimely the reason the first bridge failed, the non-fixed connection

allowed the bridge to twist and lean and cause the first bridge to fall over on

itself due to too much leaning

The double truss

structure was an idea taking from the individual bridge design portion of the

project. In the individual project one of designs was to have a single truss

structure bridge, the other was a double structure bridge. The data gather by

West Point Bridge designer showed that the double structure had a more stable

shape and only increase the cost by a minimal amount, thus giving us our basic

shape. Our final shape and size of the bridge is decided by testing physical

model and data obtained thought experimenting on the bridge designer website.

Using the data we gathered in latter we were able get the data we need and

improve the bridge without test our real bridge and having to go through

rigorous trial and error. This also helped avoid wearing down the pieces and

accidentally damage and weaken them avoiding possible unwanted failures but to

the condition of the pieces. Of course theory can only go so far so physical

test must be done as well. We did test our bridge use reams of paper (500 pages

of standard computer printer paper) and book. Upon weighting the books on a

scale we found our bridge could hold a load a bit above 30 pounds. It is a good

number base on the low cost of the bridge.

Final Design

The

final design was a top and bottom truss bridge, which used a fair number of

pieces, more than the bare minimum but far from excessive to keep the cost to a

minimal. The connection between the two halves was by fixed connection on the

top, middle, and bottom rows. It also had a few non fixed connections spanning

across the halves, this was done to save money and through testing was found

that having so few would not compromise the bridge strength and cause it to

possible twist or lean to one side when weight was added leading to a premature

failure. The idea behind the top and bottom truss is that the more connections

there are the more ways the weight’s force can travel, having both a top and

bottom mean that the main area the weight will be focused, that being the

center and central top have more options to escape to and the weight will be

distributed to the top and bottom and could be sent to the end in more options.

This design did work much better than just having a top or bottom truss in

testing thus it was chosen as the favorable shape.

Figure 3. Final Design in Final Test

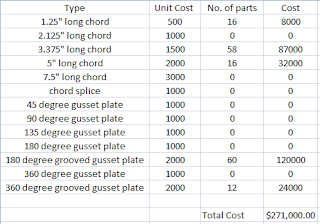

Below

is a table of the parts, number of the parts and the cost, with the total piece

count and cost at the bottom of their respective columns. Final piece count was

196 and the final cost was $307,000.

Table 1: Bill of

Material

Testing Results

The

load at failure of the final design was 17.0 pounds. The failure was around the

center area and towards the bottom of the bridge and was the result of two

grooved gussets being pulled apart as shown below. A very small and simple

failure that resulted in the bridge remaining whole and simply falling through

the span rather than violently being ripped apart and being almost completely

destroyed in failure. In terms of bridge failures this was a very calm and more

favorable break.

Figure 4. Failed Connection

Conclusion of Results

The

final test did not behave as predicted and did not behave like any of the

previous tests. In terms of the load the final design only held 17.0 pounds

where the final version of the twenty-four inch span held 34.0 pounds. The

final design only preformed half as well as the twenty-four inch span model

meaning the design did not improve but rather became worst. The predicted load

was forty pound, which was on the high side, thought multiple test on the final

design prior held an average of around thirty to thirty-five pound, in which forty

pound would not be too far off. This final test was most likely the fluke of

all the testing and may be due to how the bridge failed.

In

many of the prior test and the twenty-four inch span test failed very close to

the ends of the bridge due to all the surrounding members being pulled out of

the gussets and the center falling straight down, usually resulting in a clean

break leaving the bridge in two or three solid pieces and no single loss member

or gusset. In the final test however, the grooved gussets pulled apart from

each other around the center of the bridge, leaving it whole but with pieces

not fixed together. The image below shows where the bridge normally failed (in

blue) and where it failed in the last test (in red).

Figure 5. Usual Failed Connections and Final Test Failed Connections

The bridge only failed in

the center area and because of grooved gussets being pulled apart once during

all the prior testing. The conclusion as to why it failed like this is either

due to a missed defect prior to testing or some small difference in this test

that did not occur in the previous tests. Regardless, the final test did not

behave as the previous test had shown, but that is just how things work out and

so long as we can learn and understand from this failure there is always room

for improvement in the future.

Future Improvements

Given

the chance to modify our design to another version, the largest change would be

to build a bridge with only one truss. The two truss worked but when it counted

seemed to fail up to its standard and the extra pieces added a fair cost to the

bridge, making a one truss bridge would save money and that saved money could

be use to add extra support to critical areas such as the center and ends and

would allow for more cross connections between the two halve stabilize the

bridge, and we feel confident that a one truss bridge

could hold more than the final test did and even save money.