This week we built and tested our individual designs to see what

was the best and what were good components of the design. Upon reaching l

design and testing it, we found that the ends were the weakest and failed after

a few pounds and the grooved gussets were pulled apart easily so to make it stronger

at the gusset and cheaper we will use non grooved gussets and to help with

support we made the pieces between the gussets shorter. This will make it more

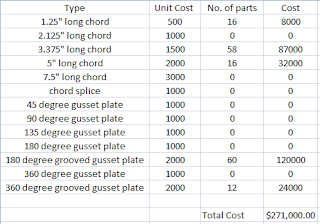

stable, compact, and cut cost, but this will require more pieces which will

increase the cost a bit but not over the original design.

I feel the same about what I stated last week about WPBD and

K’NEX, both are fairly different and the K’NEX is much more restrictive. The difference

with Steel and the K’NEX is that the steel would allow for customization of length

and gussets and thus give more options it rather than just ten fixed pieces. At

the same time give many more options and starts to be a bit like WPBD in that

you have price dependent on weight rather than piece and you have to pick solid

or hollow and the length and it becomes more complex to figure out the bridges strength.

Next week we will be testing our K’NEX design for the two

foot span, followed by going back to improve our design and prepare for the

final test with the three foot span.

- Kyle Hayes