Last week in class we listened a speech

about how to find use information about our bridge design. Mr. Jay Bhatt come

and shows some useful book that we could look at. I also got to know that our library

have a lot of useful thing I can look at to improve my knowledge of bridge. Then

we learn about the basic rule about the k’nex bridge design. like how long

should it be and how to find out how many weight it can keep with out break it.

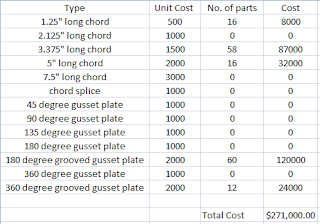

The cost of the bridge is also a big part we get look at the sheet of the cost

of each part. The last part of class we get a change to play with the K’nex.

Next

class we would really start built our own bridge. We would try to finish the

bridge in class. Try to find the best bridge with can hold more weight and cost

less.

The

k’nex is different from the WPBD by many ways. The k’nex did allow you to

changer any of the size of the bridge. You have only one size over all. Also

the really K’nex bridge did allow you to text it over and over to get a best

type. The WPBD would tell you which part is weak and need to improve, but K’nex

will not. K’nex is more really, it is a really thing than just a program. It

also made it harder because it is really not ideally any more. You need to

think more carefully of every peace. There would be a lot of unexpected problem

appear, but I am ready to handle it.